The competition in the shoe industry in the next ten years will be the competition of supply chain efficiency.

In the era of digital intelligence, from digital sample rooms, smart cutting solutions for synthetic materials, leather cutting, visual intelligent re-cutting solutions, Multi-layer cutter solutions, data-driven system analysis... choose Emma to help you reshape New competitive advantages for enterprises.

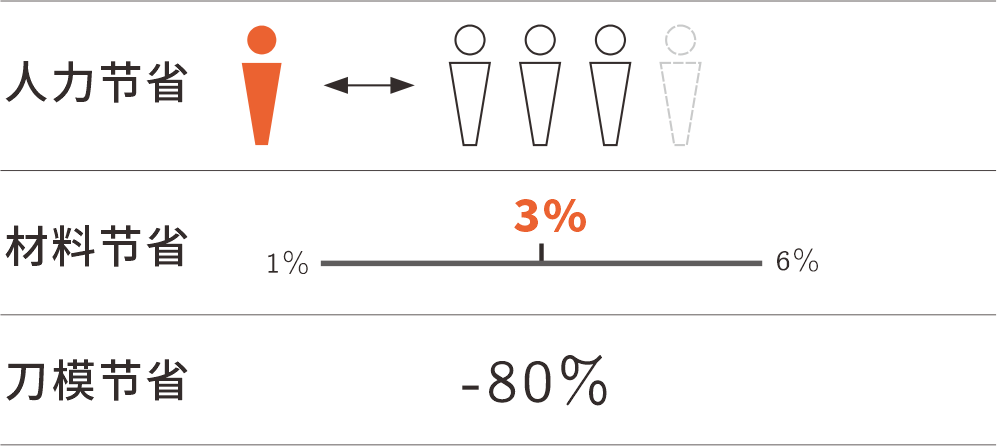

1) Oscillating knife cutting can’t replace all of the other cutting devices. It's a good way to cut most of the synthetic material. But for some material or procedure, other cutting devices might be more effective.

2) Groups formed by 3 to 4 machines are most effective. In the early stage when the investment is only 1 machine the assessment has pure value of reference.

3)Besides saving manpower, saving material, saving die-cut mold, other added value like saving time, better quality, all size and rounds, management in digital should also be considered when assessing.

| Traditional mode | Intelligent mode |

|---|---|

| order form 5000double Material preparation:2day |

50roundx100double Material preparation:2hour |

Advantages: 1) Multiple rounds; 2) Switch styles and sizes at any time; 3) Eliminating knife molds

the return of investment could not base on saving cost. Only when the investment is big enough(1+2+4), the saving of human source and material would be seen. In an smaller investment (1+2), return would barely show. The cost could equal traditional cutting at this point. We should focus on time saving, controlling cost accurately, better quality and added value.

cutting, punching, pen marking all in one machine.

Easy to switch between big production and small production in variety of styles.

High cutting precision, high quality, high efficiency.

Control the leather very closely, less dispute with supplier and customer.

Same standard for facilities in different locations.

Low cost and convenience for cross regional and cross-border communication;

Pre-nest helps to order leather more accurately, avoiding leather waste or short stock.

Easier to train beginners.

Establish digital leather warehouse, leathers of certain quality grade could be assgined to the proper style to improve the yield.

Kind reminder: In the nature of leather, the stretching, the grain and color varies on each piece and even on the same piece of leather. There still doesn't exist a technology that could perform automatic nesting with strict conditions of color matching and grain matching. Some rules and applied to achieve acceptable result of color matching and grain matching. If a company is looking to meet a very high standard of strict color/grain matching, be prudent when considering smart cutting system as the manner to achieve this goal.

Time saving, reduce modification;

High precision, high quality, high efficiency;

Digital management;

Communication between facilities in different regions/countries is cheaper and easier;

Much easier to store, retrieve and modify designs/files;

Improve company image;

More added value;

“r&d first”, prepare for “the core of automation-data source” in the time of industry 4.0 ;

Build the “constantly improving platform”;

Easier to train staffs, save and pass along the experiences;

Tip: The return of investing in a digital sample room should not be focused on saving cost. There is very limited room for cost saving. Time saving, better quality, added value and being more competitive are more important points for evaluating the return of investment.