icompatible

EMMA's unique format converse technique Which is compatible with the major software in the market, undifferentiated, non-deformation, save system conversion cost for customers.

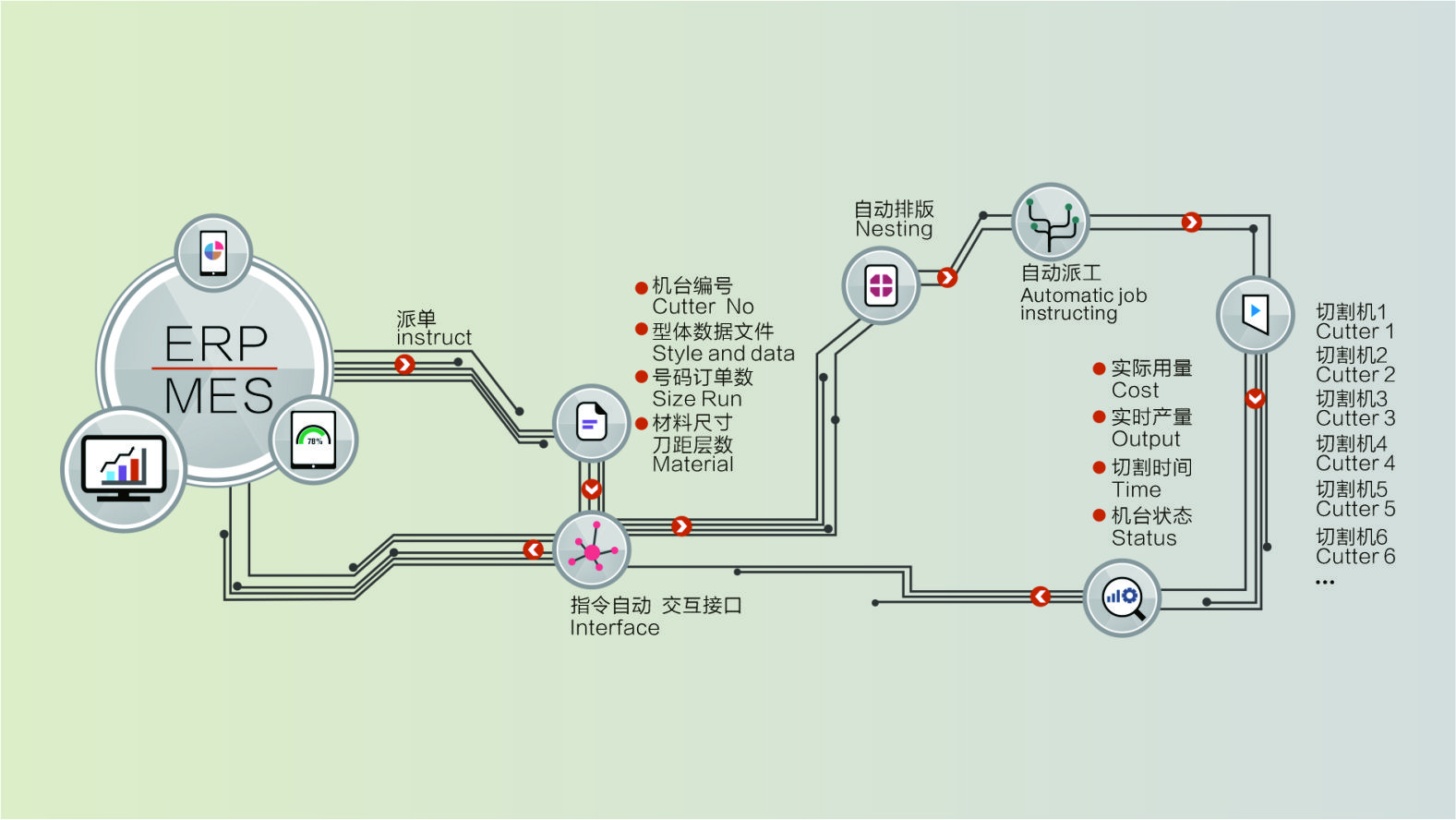

iwork

EMMA's intelligent working system, seamless connect with customer's ERP/MES system, auto import/export real time data, help customer to get Comprehensive information by analysis tools.

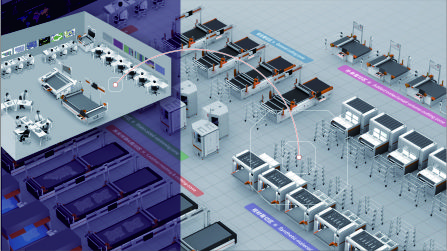

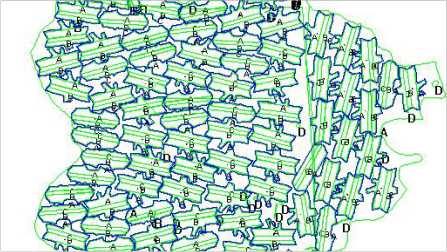

idispatch

Smart order dispatching technology —— Emma provides intelligent order dispatching technology, help customer to establish a full-material smart cutting center, and achieve the full rate of scheduling, the rate of complete sets of materials, and the lowest material consumption rate.

ismart

Emma's "Smart cutting 4.0" intelligent order dispatching & scheduling technology make the "customization-in-volume mode" possible and greatly optimize production efficiency.

ianalyze

Data for real time cutting progress exporting: real time progress of each shoe style, working status of each cutting machine, activation of each machine, efficiency of operator, statistics of unqualified pieces. And provide multiple graphical tables to display: pattern output, machine OEE, machine output, and other analysis data for the reference of managers.

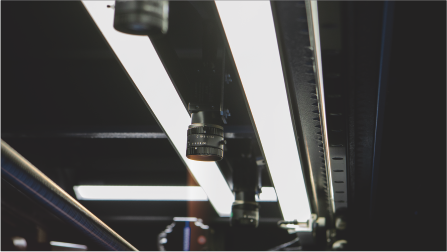

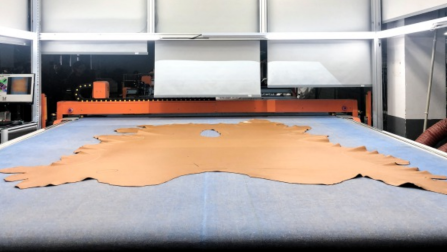

Iphoto

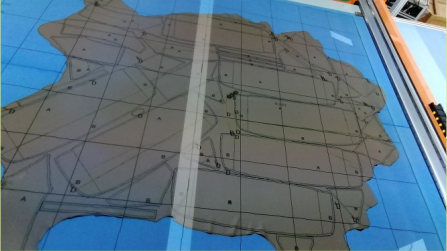

Instant photography through ten millions HD digital cameras and shots, making the leather's actual shape and defects visible.

Imarks

EMMA's unique recognition technique with touch screen. Can mark the defects and zones of different grades on leather. Finishing nesting on a 60 sq feed leather within 2-4 minutes.

Identify

Emma's unique leather identification technique, fast recognize leather shape and mark defects through high-definition photos.

Iscan

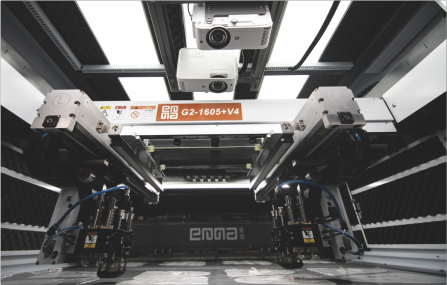

EMMA'S new generation technique of leather array camera scanning, which can scanning the defects, profile, area and so on data, digitalize leather fast and clearly.

Ivision

EMMA's new technique to vision recognition, can identify the patterns in the cutting parts, extract features, recognize and cut precisely .

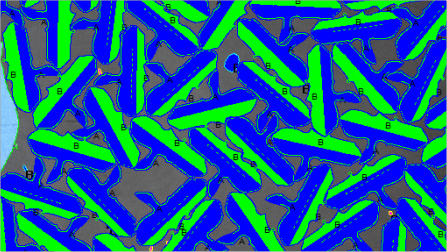

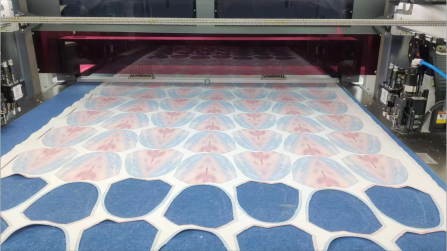

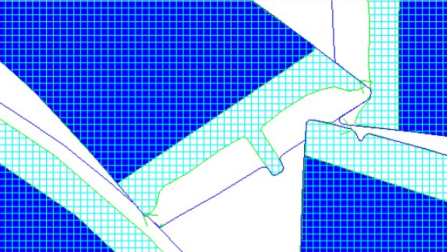

Inesting

EMMA's unique nesting technique save 90% time of work and increases 1%-6% the utilization ratio when compare to manual nesting.

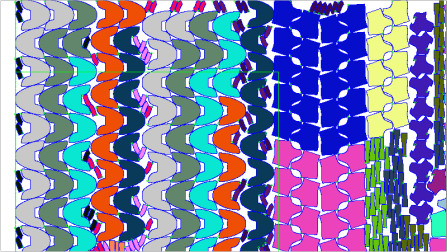

Iwin

A new multiple-core Cloud technique created by EMMA,2-4 times faster than inesting, increase 1-6 % of utilization ratio compared with manual nesting.

Imatch

Emma has developed the latest intelligent typesetting technology for leather color/pattern matching needs in footwear, which can achieve intelligent dual typesetting and match the typesetting experience of skilled workers, achieving a breakthrough in industry applications.

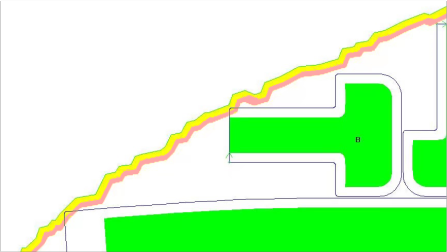

Idual

This technology can improve the utilization rate on the basis of effectively controlling the cutting quality through: 1) the edge of the leather outline in grades, 2) set the nesting knife distance in different positions on the edge of the internal parts.

Developed for nesting in the direction of leather extension ,realize the nesting of the combination of parts with multiple specified directions in a piece of leather.

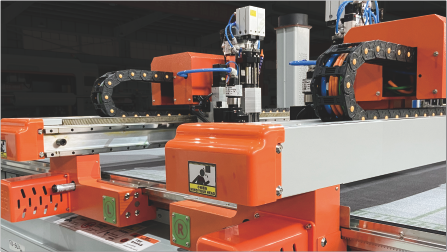

ifast

EMMA's unique CNC mathematical technique works 15% faster than similar machines in the market, increase the work efficiency.

Imore

Emma international's leading multiply cutting technology can cut sponges within 40 mm, fluffy materials within 25 mm, and solid multiply flexible materials within 10 mm.

Iquiet

EMMA's unique technique for “mute” cutting, only 72-76 decibels.

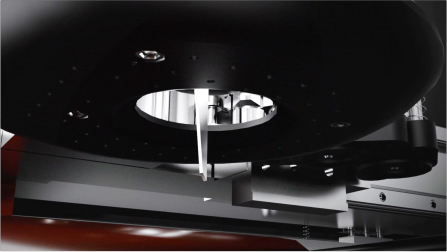

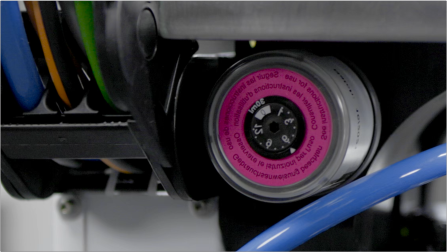

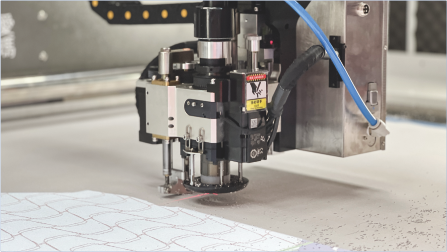

Gemini

Emma's new generation of integrated cutting head with "invention patent". The "pisces" knife have seven tools (four punching knives with different diameters, one pinholes tool, one set of pen , and one set of cutting knives).it is controlled by a precision screw. Low noise, precise position, fast speed, and high punching quality. It will be configured on EMMA's "victor", "pioneer" and " pathfinder " series of high-end models.

Isave

EMMA's unique technique to merge lines, decrease the cutting heads moving distance maximum, improve cutting efficiency significantly.

Imerger

EMMA's unique technique to merge lines, decrease the cutting heads moving distance maximum, improve cutting efficiency significantly.

Imax

Emma international's leading multiply cutting technology can cut fluffy materials within 70 mm and solid multiply flexible materials within 30 mm.

Pisces

Emma's new generation of integrated cutting head with "invention patent". The "pisces" knife have seven tools (four punching knives with different diameters, one pinholes tool, one set of pen , and one set of cutting knives).it is controlled by a precision screw. Low noise, precise position, fast speed, and high punching quality. It will be configured on emma's "victor", "pioneer" and " pathfinder " series of high-end models.

Ical

This technology installs the knife calibration structure and uses software to do knife calibration after replacing the blade quickly and automatically , saving manual correction time, reducing human error, effectively extending the service life of the cutting mat and improving work efficiency.

Icleam

This technology solves the global industry problem of material and environment pollution caused by side leakage of fine chips from punching multiply materials. The patented structure absorbs punching chips from the top to maintain the punching effect while avoiding side leakage of fine chips from polluting materials and the environment.

Icollect

Projection display on the cut leathers: the same part, the same size, the same pairs , the same set number and other inspection methods can be switched freely, which is conducive to the convenient collection and arrangement of cut pieces.

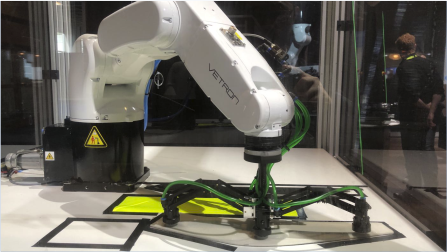

Iloading

The automatic grasping technology of the robotic arm driven by the connection between EMMA and the smart cutting machine can realize the fully automated production process of automatic feeding, automatic cutting by visual recognition, and automatic grasping and stacking.

Ilubricate

An automatic lubricating device is added to the transmission structure to keep the machine lubricated for a long time and prolong the service life of the equipment.

Idrive

Dual-servo-per-bridge driving technique of faster response and higher accuracy, translating into a 10-15% increase in cutting output over one-servo-per-bridge.

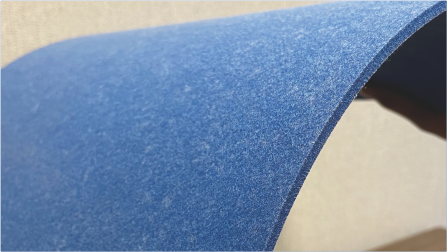

Isolid

By adding a fine anti-pulling mesh to the cutting mat, making the cutting mat stronger and more solid, effectively maintaining the transmission precision of the cutting mat and reducing the degree of deformation after cutting.

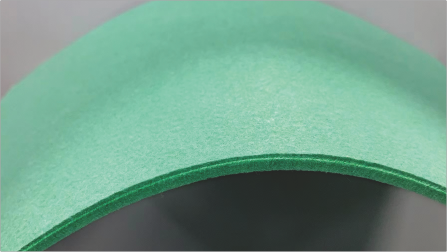

Idurable

Emma's specially formulated cutting mat manufacturing technology incorporates a new process to make it stronger and more durable. It effectively extending the life of the cutting mat.

Ieco

Using fibers re-manufactured with recycled drinking water bottles plus specially eco-friendly formula, Emma is exploring a sustainable path by incorporating a new process into the cutting mats to keep them strong and durable.

Ipunch

This latest high-speed punching technology can reach a punching speed of 5-8 holes per second (depending on the location and shape of the holes). With a special device, it could also make punches of non-circle shape of certain position. It's suitable for sports shoes U-shaped holes and all kinds of shaped holes on hand bags.

ilapping

and development, includes practical functions such as "multi-edge overlapping, double outline settings, and multi-grades settings". It is comparable to the traditional lapping-knife cutting mode. Save more leather without affecting the quality

iconvey

It solves the problem that in the past there was no adsorption function when leather was transferred, and the leather was deformed due to switching between relaxation and adsorption, requiring secondary positioning, and improved production efficiency.