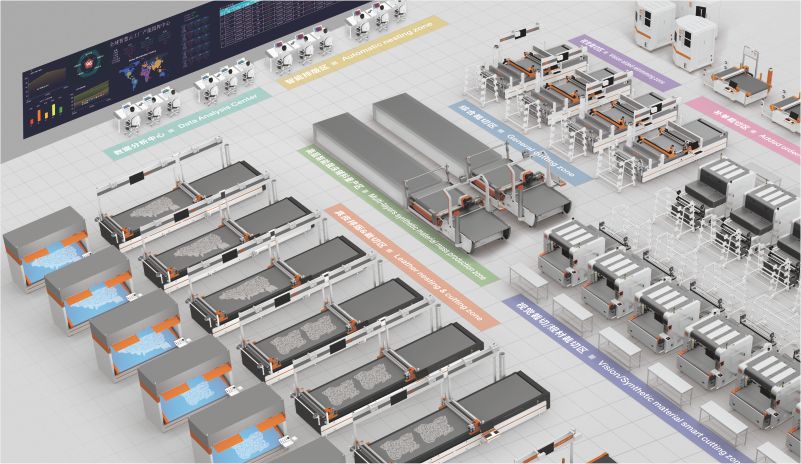

Emma's team of senior professional consultants, best practices in different industries, and strong data analysis and utilization capabilities help customers plan data flows starting from top-level design when building smart factories in the Industry 4.0 era, and help customers integrate information starting from the design end. Go to the production site and provide real-time feedback to the management to reduce repetitive work and improve overall competitiveness.

Senior professional trainer provide training to customer systematically which include: CAD personnel, grading personnel, nesting and calculating for material personnel, machine operators…Help customers introducing smart cutting system smoothly and provide support constantly, enable customers to create technique competitive advantages.

Experienced and energetic EMMA service team, provide pre-sales technical test, proposal, programming; installation and debugging, training, production service; After-sales, maintenance, technical support, function upgrading and so on whole process service. Help customer introducing smart cutting system smoothly and provide support constantly, enable customers to create technique competitive advantages.

According to the actual development needs of customers, combined with Emma's technology upgrades, and in response to changes in customer styles, materials, and production capacity, we provide customers with component upgrades, tool upgrades, system upgrades, technical transformation and other services within the scope of conditions permitting. Help customers extend equipment functions, improve production efficiency and make full use of equipment, ensure customers' maximum production efficiency, maintain maximum application within the scope of equipment capabilities, reduce costs, and maintain optimal equipment utilization.

With our experience, we help the customers to build a management team to stay on trend in the industry, establish division of labour and a digital work flow that fits, to ensure the introduction of cutting system goes well.

Emma has established 8 regional technical service centers in China, which can provide efficient technical support to customers in more than 50 cities. The Emma brand has been registered in many countries and regions around the world, and works closely with many regional agents to provide high-quality and timely services to customers in many countries around the world.

In 2023, Aiyun Service, a digital service system independently developed by Emma, will be officially launched to provide digital intelligent management services for smart cutting machines. The operating data of the system can be detected online 24 hours a day. When the equipment have problem or needs maintenance, it will automatically send an early warning message to the mobile phone. You can also remotely manage the machine, check the machine's operating parameters online, and automatically generate management reports to ensure the safe and stable operation of the machine and escort your enterprise production.

Respond within 12 hours of receiving problem reports on working days, well understand the problem, and provide preliminary suggestions.

Online remote services include but not limited to maintenance, testing, software installation and other services, with no time limit, the goal is helping customers solve problems.

For commonly used models of consumables and accessories, we will deliver them within 3 days after receiving customer orders/requirements. Except for delays in payment.

The software will be upgraded to the latest compatible version for free within 3 years after machine acceptance.