Idrivve

Dual-servo-per-bridge driving technique of faster response and higher accuracy, translating into a 10-15% increase in cutting output over one-servo-per-bridge.

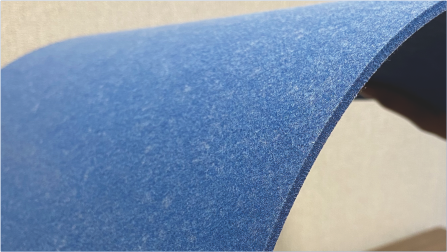

Isolid

By adding a fine anti-pulling mesh to the cutting mat, making the cutting mat stronger and more solid, effectively maintaining the transmission precision of the cutting mat and reducing the degree of deformation after cutting.

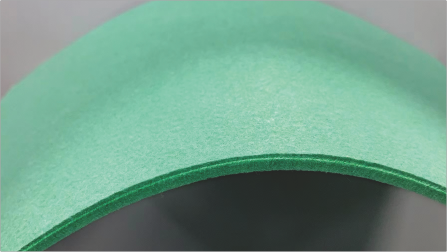

Idurable

Emma's specially formulated cutting mat manufacturing technology incorporates a new process to make it stronger and more durable. It effectively extending the life of the cutting mat.

Ieco

Using fibers re-manufactured with recycled drinking water bottles plus specially eco-friendly formula, Emma is exploring a sustainable path by incorporating a new process into the cutting mats to keep them strong and durable.

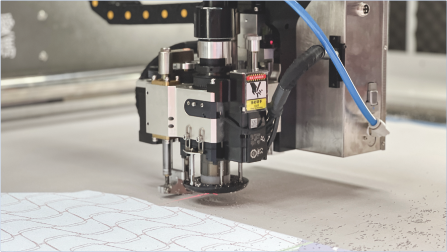

Ipunch

This latest high-speed punching technology can reach a punching speed of 5-8 holes per second (depending on the location and shape of the holes). With a special device, it could also make punches of non-circle shape of certain position. It's suitable for sports shoes U-shaped holes and all kinds of shaped holes on hand bags.

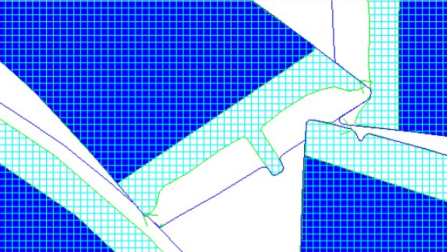

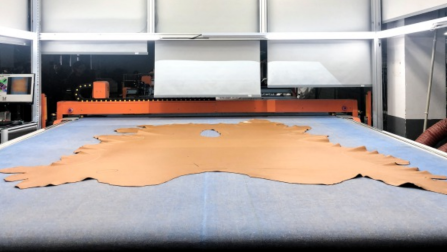

ilapping

Emma's breakthrough auto nesting and cutting technology, which took fifteen years of research and development, includes practical functions such as "multi-edge overlapping, double outline settings, and multi-grades settings". It is comparable to the traditional lapping-knife cutting mode. Save more leather without affecting the quality

iconvey

It solves the problem that in the past there was no adsorption function when leather was transferred, and the leather was deformed due to switching between relaxation and adsorption, requiring secondary positioning, and improved production efficiency.